Why Konan PHM is

your best choice?

Konan PHM enables real-time monitoring of equipment

and component conditions, allowing anomaly detection

and fault diagnosis even in data-scarce environments. It

helps reduce unexpected failures and maintenance costs

across industries such as defense, steel, and railway.

By combining Digital Twin technology with advanced AI (PBDL and RL),

Konan PHM supports decision-making for fault diagnosis and remaining useful life prediction of

equipment and components. It delivers Data-Centric AI that can accurately represent equipment conditions without requiring deep domain expertise.

Video - From Monitoring to Predictive Maintenance, Konan PHM

BENEFITS

Benefit 01.

Overcoming Data Limitations

Even with insufficient failure or labeling data, Konan PHM enables fault detection

and diagnosis using technologies such as Self-supervised Learning, Physics-

informed Neural Networks, and Domain Adaptation.

Benefit 02.

Maintaining Model Performance

Konan PHM continuously monitors the performance of AI models in operation.

When degradation occurs due to component/system aging or other factors, it

performs Model Updating procedures through data re-training.

Benefit 03.

Real-time Simulation

By leveraging state-of-the-art AI modeling technologies such as Neural Operator,

Konan PHM provides data-driven real-time simulations, enabling rapid and

reliable decision-making.

FEATURE

-

Need

Early alerts before equipment/

component anomalies occur -

Issue

Manual maintenance management

by on-site operators -

Current

Status Unclear maintenance records,

Low quality due to lack of labeling data -

Approach

Utilize unlabeled validated normal

data exclusively for anomaly

detection - Technology Anomaly Uncertainty Scoring

-

Need

Identify equipment/component anomalies during

failures - Issue Lack of failure occurrence data

-

Current

Status Difficulty in securing failure data,

Inability to train classification models -

Approach

Apply simulation-based virtual data to overcome

Domain Shift with actual data -

Technology

Data-driven Simulation, Domain

Adaptation

-

Need

Prediction of outcomes under changing product

parameters - Issue Difficulty in performing real-time simulation

-

Current

Status High-cost model-based simulation, Inability to run

real-time simulations during operation -

Approach

Apply advanced Data-driven simulation technology that

reflects physical characteristics - Technology Data-driven Simulation

ARCHITECTURE

| Authentication (ATU) |

Tenant Manage ment (STM) |

Equip ment Monitor ing(SMD) |

Compo nent Monitor ing(BMD) |

AI Analyt ics (PHM) |

Data Visual ization (DVD) |

|---|---|---|---|---|---|

| Login Processing | User Manage ment |

Equipment Status | Component Status |

AI Anomaly Detection | Data Selection/Comparison |

| Token Issuance | Group Manage ment |

Asset Status | Sensor Data Graph | Data Health Indexing | Sectional Settings |

| Token Verification | Permission Management |

Fault Status | HI Graph | Alarm Leveling | Convenient Functions |

| Common (CMD) |

Billing Management | 2D/3D Modeling | Fault Time Graph | Digital Twin Configuration (TIC) |

Data Refresh |

| System Structure | Resource Usage Management | Alarms | Settings | IoT Registration/Update |

Device Status

Device Information

|

Kubernetes(PaaS)

KT Cloud(IaaS)

Konan MLOps

Data Processing

- Data Cleaning

- Data Normalization

- Data Reduction

- Data Transformation

Model Training

- Anomaly Detection

- Remaining Useful Life Prediction

- Fault Diagnosis

- Collection

- Data Query

- Training Data

- Training

- Evaluation

USE CASES

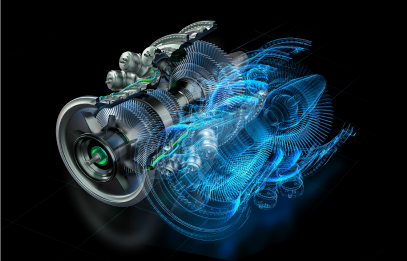

Defense –

Prediction of Fighter Jet Structural

Vibration Response

- Background

- Structural vibration testing is required to ensure the

structural stability of fighter jets, but there are

limitations due to time and cost constraints. - Problem

- Predicting structural vibration responses of new

aircraft through limited structural vibration testing. - Approach

- Develop a hybrid model combining Neural

Operator–based Data-driven structural vibration

learning and structural dynamics control theory.

Steel –

Press Equipment Anomaly Detection

(Pre-Failure)

- Background

- Collection of large-scale sensor data (200 PLC units) generated from press equipment.

- Problem

- Using PLC data to predict failures before

malfunctions occur in press equipment. - Approach

- Develop tools and indicators by analyzing

anomalies in press equipment with data from 200 PLC sensors.

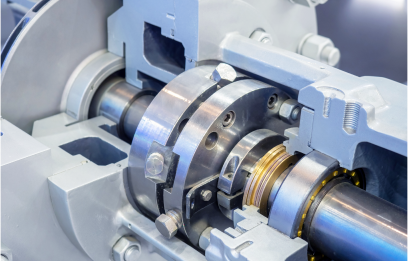

Rail –

Motor Bearing Anomaly Detection

(Pre-Failure)

- Background

- Fe content in motor bearings must be periodically measured, and replacement is required if it exceeds the reference threshold.

- Problem

- Predict future abnormal increases in Fe content to forecast early failures prior to the next scheduled inspection.

- Approach

- Developed features for predicting Fe content and designed algorithms based on complexity rules, machine learning, and deep learning.